ENEL

Conversion plan to CCGT and clean coal technologies: a path towards energy efficiency

Enel is completing a plan to convert its oil-fired power plants into both CCGTs and very efficient coal-fired plants.

With reference to the CCGT plan, as of December 2004, the total capacity of ultra-high efficiency (55%) natural gas-fired combined-cycle plants exceeded 5,000 MW. This capacity will grow by another 1,100 MW within 2007.

The conversion of the original conventional oil-fired power plants will cut specific CO2 emissions by over 50% and reduce SO2 emissions practically to zero.

The table below compares the oil-fired power plants with the CCGT and shows the benefits of the latter.

| Oil-fired power plant 300 MW | Natural gas-fire combined cycle plant 300 MW | ||

|---|---|---|---|

| Efficiency | 38% | Efficiency | 56% |

| CO2 emissions (g/kWh) | 740 | CO2 emissions (g/kWh) | 360 |

| Total CO2 emissions | 1.30 Mt/y | Total CO2 emissions | 0.65 Mt/y |

| CO2 emissions (g/kWh) | 740 | CO2 emissions (g/kWh) | 360 |

In order to safeguard the security of fuel supply and lower the cost of electricity, Enel also started, in 2004, the conversion of about 4,000 MW of oil fired power plants into coal-fired power plants.

Enel adopted the ’clean coal technology’, that delivers the same quantity of electricity by burning less coal, thanks to optimization of thermodynamic cycle (Rankine cycle) and use of new equipment and materials: that enables, inter alia, the reduction of CO2 emissions. Furthermore, the “clean coal technology” includes also both the desulfurization and denitrification systems to cut down on stack concentrations of SO2 and NOx. Bag filters, which are more efficient with respect to the abatement of thin particulates, are also installed.

In particular the new Enel coal-fired power plants will be equipped with :

- Ultra-supercritical boilers, allowing both high temperature (about 600 °C) and high pressure (about 260 bar), with the effects of a much higher efficiency (45% versus the present 38%) and outstanding savings of fuel;

- Desulphurization systems to reduce sulphur dioxide;

- Denitrification systems to reduce NOx;

- Bag filters to cut down the particulates;

- Crystallization systems converting sludge from the desulphurization process into dry non-hazardous waste;

- Coal handling aimed at avoiding emissions of fugitive dust into the atmosphere.

| Oil-fired power plant | Clean Coal-fired power plant | |

|---|---|---|

| Net efficiency | 38% | 45% |

| Fuel | Oil 0.23$ S | Coal 0.3÷1% S |

| Desulfurisation systems | NO | Yes (η = 97%) |

| Denitrification systems | Yes (η = 80%) | Yes (η = 85%) |

| Particulate abatement systems | Electrostatic (η = 90%) | Bag filter (η = 99.9%) |

| CO2 emissions | 740 g/kWh | 770 g/kWh |

The slight increase in CO2 emissions will be compensated by the sharp decrease coming from the CCGT conversions.

Ontario Power Generation

Energy Efficiency Savings at Ontario Power Generation

OPG’s Sustainable Energy Development Policy and Code of Business Conduct require continual improvement in energy and resource use efficiency.

OPG is the largest consumer of its own electricity and improvements in energy efficiency offer significant opportunities for reducing operating costs, increasing productivity and profits, and enhancing environmental performance.

OPG has an established multi-year track record in internal energy efficiency. The company’s total cumulative energy savings since starting its energy efficiency program in 1994 are close to 3,000 GWh, with monetary savings of $124 million per year (@ 4.3 cents per kilowatt-hour) and annual emission savings of 2.9 million tonnes of CO2.

In 2004, OPG achieved internal energy savings of 107.4 GWh (equal to approximately two per cent of its internal energy use, which exceeded its self-imposed energy efficiency target of 45 GWh.

Since OPG does not sell directly to residential customers, its energy-efficiency programs are focused on large industrial customers, and advocacy, education and information programs. To encourage energy efficiency in the building sector, the company has sponsored the Healthy House Award to recognize the environmental benefits of home energy savings.

OPG has also sponsored energy efficiency initiatives in its station communities, school-based educational programs which teach students and their families ways to conserve energy and water, employee training sessions and home energy audits to encourage employees to adopt residential energy efficiency measures.

OPG also sponsors an On-Line Energy Efficiency Center through the Canadian Energy Efficiency Alliance (www.energyefficiency.org) to provide users with easy access to energy efficiency information.

OPG works with an extensive alliance network to promote the wise use of energy. These stakeholders include Natural Resources Canada, major customers, and industry members of associations such as the Canadian Industry Program for Energy Conservation, Canadian Energy Efficiency Alliance, Alliance to Save Energy, Consortium for Energy Efficiency, American Council for an Energy Efficient Economy, and the Electric Power Research Institute.

Since the start of the program in 1994, OPG has completed more than 300 energy saving projects in its offices and nuclear, fossil and hydroelectric stations. Energy saving projects fall into two categories :

- Electrical Efficiency improvements that save electricity

- Thermal/Conversion Efficiency improvements that improve heat rates in nuclear and fossil plants, save fuel in hydroelectric stations.

One example of an electricity efficiency improvement is the lighting upgrade project at OPG’s coal-fired Lambton Generating Station. This project replaced over 9000 open strip fluorescent fixtures with high efficacy, high Color Rendering Index, low maintenance metal halide fixtures.

The project delivered four times more light with 80% fewer lamps and 60% less energy consumption. Other benefits have included a brighter, safer workplace and lower maintenance costs. The energy savings over the life of the project are estimated at 60 GWh.

Fossil unit improvements were mainly from boiler, turbine, and heating, ventilation and air conditioning system performance upgrades. In 2004, turbine upgrades at the coal-fired plant, Nanticoke GS Unit 7, increased its Maximum Continuous Rating from 475 MW to 495 MW.

Nuclear improvements were largely in boiler operation (e.g., reduced boiler blow down) and generator operation. In Hydroelectric, many of the upgrades involved increasing capacity, and optimized conversion effectiveness through runner replacement.

Initially, there were many internal challenges to advancing energy efficiency. Barriers included energy use accounting, monitoring, awareness, and use of cost centers. To develop an effective and comprehensive program, OPG worked to address five factors :

- Attention – No time or incentive because the focus was on electricity production

- Affordability – No money for projects because the costs of inefficiency were hidden

- Awareness – Unknown opportunities because of a focus on generation rather than conservation

- Attitude – Not part of my business, cost centers were separated from areas where energy was used

- Accountability – Energy efficiency was not measured, energy use was often unmetered

Results

OPG’s internal energy efficiency program was launched in 1994 with a target energy savings of 700 GWh over four years. Energy savings of 293 GWh/yr in the first year surpassed the original target by 67%. The annual targets now reflect more aggressive savings and projected business-planning results.

Lessons learned from the development and implementation of OPG’s Energy Efficiency program include :

- Long-term success requires integrating energy efficiency into every day business practice with annual targets and contributions from all parts of the Company

- Guidelines and incentives help promote energy efficiency in business units

- Credibility requires a well defined energy use and efficiency tracking system

RAO UESR

** Contribution to be determined **

TEPCO

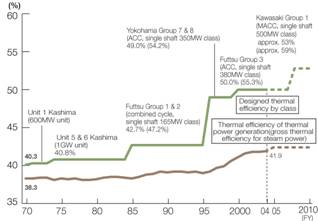

Improving thermal efficiency at thermal power

TEPCO has been striving to raise thermal efficiency while continuing technical development and improvements such as introducing combined cycle gas turbine (CCGT) generation and high efficiency coal fired plant. In FY 2004, TEPCO maintained the energy efficiency level of 41.9% (Higher Heating Value), weighted average of all the thermal plants of TEPCO. This high level is mainly achieved by the operation of efficient Advanced Combined Cycle (ACC) power generation introduced since the late 1980s.

TEPCO is making further attempts to improve thermal efficiency by deploying ACC power generation facilities and gradually starting of operation of 1,450°C class More Advanced Combined Cycle (MACC) power generation facilities.

TEPCO is constructing a 1,450°C class MACC plant at Kawasaki power site. MACC power generation boosts a thermal efficiency to around 53% (based on Higher Heating Value), the highest level in the world. Reflecting its track record in 1,100°C class CC power generation and 1,300°C class ACC power generation, TEPCO is attempting to develop new technology and improve equipment for MACC power generation.

In addition to gas fired CCGT, TEPCO is also undertaking the improvement of cal fired plants. The Hitachinaka Thermal Power Station, which started its operation in December 2003, is Japan’s largest scale coal fired thermal power station, with an capacity of 1GW. It achieves a thermal efficiency of 43% (Higher Heating Value), the highest level for coal thermal and thus helping to reduce CO2 emissions.

e7 Group

Improving the Energy Efficiency of Jordan’s Power Plants

In February 1996, the e7 initiated a project to help the Hashemite Kingdom of Jordan to improve the efficiency of its oil-fuelled electricity generating units. Completed in 2000, the project has reduced both greenhouse gas and acid gas emissions. Sustainable energy is one of Jordan’s priorities for its energy sector.

The Project

The host electric utility in Jordan, now known as the Central Electricity Generating Company (CEGCO), requested assistance3 from the e7 and agreed to register the project as an Activity Implemented Jointly (AIJ). CEGCO was concerned about heat rate and efficiency of its generating units. The Activity Implemented Jointly pilot programme was the precursor to the Clean Development Mechanisms and this AIJ project was one of the few completed worldwide.

The project was carried out at three units on two sites – the Aqaba oil-fuelled station in southern Jordan and the Hussein oil-fuelled station near Amman.

Phase 1 – Assessment and Training

Phase 1 included assessing the performance of the selected generating units and operating practices and training. It consisted of five tasks. The e7 provided the equipment needed to test the units.

- Tasks 1 and 2 involved boiler combustion optimization and boiler and turbine heat rate and efficiency tests.

- Task 3 was a water chemistry workshop.

- Task 4 included training CEGCO employees in testing and analysis to improve plant efficiency.

- Task 5 involved assistance to CEGCO to establish an energy efficiency performance test team. This team helps to maintain the improvements in performance achieved with this project and to apply the knowledge and test equipment to other units.

Data collected as part of Phase 1 were used to define baseline performance. Changes to the operation of the units during performance tests and following the test programme resulted in an immediate improvement in unit performance and a reduction in air emissions. These changes included boiler tube wash at Hussein TPS and new air pre-heater seals at Aqaba TPS.

As the programme unfolded, CEGCO staff were eager to learn the procedures and technical skills required.

The final audit of the project included interviews and reviews with operating staff to ensure that they could operate the new equipment and perform the performance monitoring. Results showed a high level of success and gave evidence that greenhouse gas reductions should be maintained and possibly even enhanced.

Phase 2 – Implementation of Recommendations

Following review of the results and recommendations from Phase 1 with CEGCO, the e7 and CEGCO selected three projects for implementation to make further efficiency improvements and reduce emissions at the Hussein Station. These projects were :

- Improvements to air pre-heaters – Air pre-heater leakage was substantial on all units tested. Improvements were centered around improved cleaning and sealing equipment.

- Installation of a monitoring system and upgrades to instrumentation – A basic computer-driven monitoring system to provide warning of any degradation in equipment performance or controllable operational efficiency losses was installed on two 66 MW units to reduce heat losses. In addition, new instrumentation was installed to ensure the monitoring system would perform properly.

- Installation of emissions measurement equipment to improve combustion instrumentation – The tests carried out in Phase 1 found that the station oxygen analyzers were inaccurate, resulting in higher boiler losses. A system to monitor carbon monoxide, oxygen and nitric oxide was installed in each of the two 66 MW units to provide monitoring data.

Results of the Project

Once the Phase 2 installation projects were complete, the total emissions savings resulting from the two phases of this project, estimated over a three-year period, are 141,983 Mg of carbon dioxide (CO2) and 3,420 Mg of sulphur dioxide (SO2).